- High efficiency vacuum hot water boiler

- Vacuum hot water boiler

High efficiency vacuum hot water boiler

KDNV-GVHEX series

Operating principle and features

- The KDNV vacuum hot water boiler encloses a fixed amount of heating medium water and keeps it in a vacuum (negative pressure) state in the boiler body. When the medium water is heated, it immediately evaporates into decompressed steam to indirectly heat the heat exchanger to provide hygienic water

Multi-purpose heat exchangers

- Heat exchangers can be used for heating, hot water supply and circulation heating in 1~3 circuits depending on the user’s demand. Each heat exchanger is independently installed and provides hygienic water without water mixing.

Low NOx burner attached as default

- Fuel saving low NOx burner is attached as default and guarantees 40ppm or less when operating under 4% of O2

Absolutely safe design

- Unlike pressure boilers, the KDNV vacuum hot water boiler operates under negative pressure (pressure below atmospheric pressure) and has no risk of explosion. 4-level safety devices (Vacuum pressure, over heat prevention, boiler body thermistor and low water level switches) further ensures the reliability of the product.

Semi-permanent life

- As the boiler water (heating medium water) of the vacuum hot water boiler is always kept in a fixed amount under vacuum condition without moving, there are no risks of corrosion or scale accumulation caused by dissolved oxygen. In addition with hygienic high corrosion resistant stainless steel heat exchangers, the boiler body is semi-permanent.

Fuel cost reduction with high efficiency furnace design

- The high efficiency body design, which adopts once-through characteristics of the water tube boiler, forms the water cooling wall structure and heat absorbing 3-pass structure, greatly reduces fuel costs.

High efficiency economizer

- Condensing economizer can be attached to the flue to drastically reduce fuel cost (Option)

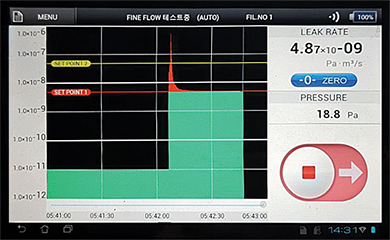

Helium gas leak detector

-

Check any leakage after processing the boiler body → Check any leakage after assembling the heat exchange r→ Check any leakage after assembling the finished product

To produce vacuum boilers with perfect vacuum condition, a helium gas leak detector is used in 3 steps during production. By using helium detector at near perfect vacuum condition of 10-3 Torr ~ 10-7 Torr, the system automatically detects even the smallest gap or air leak from the welded part, where no fluid can normally leak through.

Standard specifications for low NOx high-efficiency vacuum hot water boiler KDNV- GVHEX series

| Category | Unit | KDNV-GVHEX series | |||||||||

| Vertical Type | |||||||||||

| KDNV- 10G2VHEX |

KDNV- 15G2VHEX |

KDNV- 20GVHEX |

KDNV- 25GVHEX |

KDNV- 30GVHEX |

KDNV- 35GVHEX |

KDNV- 40GVHEX |

KDNV- 45GVHEX |

KDNV- 50GVHEX |

|||

| Boiler specifications | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | ||

| Efficiency | % | 98.3% | |||||||||

| Heating area | ㎡ | 5.43 | 5.85 | 8.30 | 8.60 | 10.10 | 10.10 | 11.20 | 11.50 | 12.00 | |

| Burner | - | KLN-200(U) | MAXI 25(LX) | MAXI 32(LX) | P4M (LX) | P5M (LX) | |||||

| Burner capacity(MAX) | kcal/h | 215,000 | 295,000 | 411,000 | 550,000 | 650,000 | |||||

| Control method | - | ON - OFF | HI - LOW - OFF | ||||||||

| Blower motor capacity | kW | 0.25 | 0.37 | 0.75 | 1.50 | ||||||

| Total power consumption | kW | 0.35 | 0.47 | 0.85 | 1.60 | ||||||

| Power | V | 220V x 1ø x 60Hz | 380V x 3ø x 60Hz | ||||||||

| Fuel consumption | LNG | N㎥/h | 10.2 | 15.3 | 20.30 | 25.40 | 30.50 | 35.60 | 40.70 | 45.80 | 50.90 |

| Propane(LPG) | N㎥/h | - | - | 9.1 | 11.4 | 13.6 | 15.9 | 18.2 | 20.4 | 22.7 | |

| Diameter | Gas inlet | A | 25 | 25 | 25 | 40 | 40 | 40 | 50 | 50 | 50 |

| Flue | ømm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 300 | |

| External size | Width(W) | mm | 1160 | 1160 | 1,300 | 1,300 | 1,400 | 1,400 | 1,550 | 1,550 | 1,550 |

| Length(L) | 1790 | 1790 | 2,030 | 2,030 | 2,170 | 2,170 | 2,690 | 2,690 | 2,740 | ||

| Height(H) | 1780 | 1780 | 2,000 | 2,000 | 2,030 | 2,030 | 2,120 | 2,120 | 2,120 | ||

| Product weight | kg | 620 | 640 | 820 | 850 | 960 | 1,100 | 1,190 | 1,210 | 1,250 | |

For heating and hot water circulation (333K → 343K) {60℃ → 70℃}

| Category | Unit | KDNV-GVHEX series | |||||||||

| KDNV- 10G2VHEX |

KDNV- 15G2VHEX |

KDNV- 20GVHEX |

KDNV- 25GVHEX |

KDNV- 30GVHEX |

KDNV- 35GVHEX |

KDNV- 40GVHEX |

KDNV- 45GVHEX |

KDNV- 50GVHEX |

|||

| For heating and hot water circulation | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | ||

| Circulation volume | ℓ | 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||

| Head pressure loss | MPa{mH2O} | 0.012{0.12} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | ||||

| Material | - | Stainless steel pipe | |||||||||

| Connection diameter | A | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | |

For hot water supply (298K → 338K) {25℃ → 65℃}

| Category | Unit | KDNV-GVHEX series | |||||||||

| KDNV- 10G2VHEX |

KDNV- 15G2VHEX |

KDNV- 20GVHEX |

KDNV- 25GVHEX |

KDNV- 30GVHEX |

KDNV- 35GVHEX |

KDNV- 40GVHEX |

KDNV- 45GVHEX |

KDNV- 50GVHEX |

|||

| For hot water supply | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | ||

| Circulation volume | ℓ | 2500 | 3750 | 5,000 | 6,250 | 7,500 | 8,750 | 10,000 | 11,250 | 12,500 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||

| Head pressure loss | MPa{mH2O} | 0.012{0.12} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | ||||

| Material | - | Stainless steel pipe | |||||||||

| Connection diameter | A | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | |

For hot water supply (278K → 338K) {5℃ → 65℃}

| Category | Unit | KDNV-GVHEX series | |||||||||

| KDNV- 10G2VHEX |

KDNV- 15G2VHEX |

KDNV- 20GVHEX |

KDNV- 25GVHEX |

KDNV- 30GVHEX |

KDNV- 35GVHEX |

KDNV- 40GVHEX |

KDNV- 45GVHEX |

KDNV- 50GVHEX |

|||

| For hot water supply | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | ||

| Circulation volume | ℓ | 1667 | 2500 | 3,333 | 4,167 | 5,000 | 5,833 | 6,667 | 7,500 | 8,333 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||

| Head pressure loss | MPa{mH2O} | 0.006{0.06} | 0.015{0.15} | 0.018{0.18} | 0.015{0.15} | 0.02{0.2} | 0.018{0.18} | ||||

| Material | - | Stainless steel pipe | |||||||||

| Connection diameter | A | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | |

-

The above specification table is indicated as follows.

- The fuel calorific value of fuel consumption is based on the following.

- Fuel: Higher calorific value _ Lower calorific value

- LNG : 11,000_10,000 kcal/N㎥

- Propane : 24,350_22,400 kcal/N㎥

- Design flow temperature condition for heating and hot water circulation 333~343K {60~70℃}

- Design flow temperature condition for hot water supply 298~338K {25~65℃}, 278~338K {5~65℃}

- The rated heat output for heating and hot water supply is given for each individual use, and in the case of simultaneous use, the total is the boiler heat output.

-

The following tolerances are included due to the measurement errors of the measuring instrument or measuring personnel.

- Boiler efficiency measurement error ±1%, fuel amount (heat input) measurement error ±1.5% - The above boiler efficiency is based on the true heat generation (low heat generation).

- The above specification table is subject to change without notice.

High efficiency vacuum hot water boiler

KDNV-G2X series

Operating principle and features

- The KDNV vacuum hot water boiler encloses a fixed amount of heating medium water and keeps it in a vacuum (negative pressure) state in the boiler body. When the medium water is heated, it immediately evaporates into decompressed steam to indirectly heat the heat exchanger to provide hygienic water

Multi-purpose heat exchangers

- Heat exchangers can be used for heating, hot water supply and circulation heating in 1~3 circuits depending on the user’s demand. Each heat exchanger is independently installed and provides hygienic water without water mixing.

Low NOx burner attached as default

- Fuel saving low NOx burner is attached as default and guarantees 40ppm or less when operating under 4% of O2

Absolutely safe design

- Unlike pressure boilers, the KDNV vacuum hot water boiler operates under negative pressure (pressure below atmospheric pressure) and has no risk of explosion. 4-level safety devices (Vacuum pressure, over heat prevention, boiler body thermistor and low water level switches) further ensures the reliability of the product.

Semi-permanent life

- As the boiler water (heating medium water) of the vacuum hot water boiler is always kept in a fixed amount under vacuum condition without moving, there are no risks of corrosion or scale accumulation caused by dissolved oxygen. In addition with hygienic high corrosion resistant stainless steel heat exchangers, the boiler body is semi-permanent.

Fuel cost reduction with high efficiency furnace design

- The high efficiency body design, which adopts once-through characteristics of the water tube boiler, forms the water cooling wall structure and heat absorbing 3-pass structure, greatly reduces fuel costs.

High efficiency economizer

- Condensing economizer can be attached to the flue to drastically reduce fuel cost (Option)

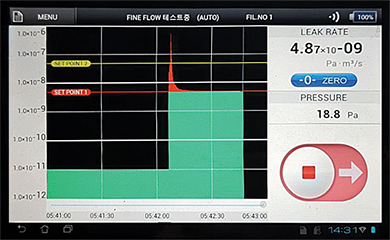

Helium gas leak detector

-

Check any leakage after processing the boiler body → Check any leakage after assembling the heat exchanger→ Check any leakage after assembling the finished product

To produce vacuum boilers with perfect vacuum condition, a helium gas leak detector is used in 3 steps during production. By using helium detector at near perfect vacuum condition of 10-3 Torr ~ 10-7 Torr, the system automatically detects even the smallest gap or air leak from the welded part, where no fluid can normally leak through.

Standard specifications for low NOx high-efficiency vacuum hot water boiler KDNV-G2X series

| Category | Unit | KDNV-G2X series | ||||||||||

| Horizontal Type | ||||||||||||

| KDNV- 20G2X |

KDNV- 25G2X |

KDNV- 30G2X |

KDNV- 35G2X |

KDNV- 40G2X |

KDNV- 45G2X |

KDNV- 50G2X |

KDNV- 60G2X |

KDNV- 80G2X |

KDNV- 100G2X |

|||

| Boiler specifications | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Efficiency | % | 98.3% | ||||||||||

| Heating area | ㎡ | 12.12 | 13.29 | 15.57 | 15.69 | 16.78 | 17.07 | 18.85 | 19.71 | 22.02 | 27.96 | |

| Burner | - | MAXI 25(LX) | MAXI 32(LX) | P4M (LX) | P5M (LX) | P60M (LX) | P72M (LX) | |||||

| Burner capacity(MAX) | kcal/h | 295,000 | 411,000 | 550,000 | 650,000 | 800,000 | 1,800,000 | |||||

| Control method | - | ON - OFF | HI - LOW - OFF | |||||||||

| Blower motor capacity | kW | 0.37 | 0.75 | 1.50 | 3.00 | |||||||

| Total power consumption | kW | 0.47 | 0.85 | 1.60 | 3.10 | |||||||

| Power | V | 220V x 1ø x 60Hz | 380V x 3ø x 60Hz | |||||||||

| Fuel consumption | LNG | N㎥/h | 20.30 | 25.40 | 30.50 | 35.60 | 40.70 | 45.80 | 50.90 | 61.00 | 81.40 | 101.70 |

| Propane(LPG) | N㎥/h | 9.1 | 11.4 | 13.6 | 15.9 | 18.2 | 20.4 | 22.7 | 27.2 | 36.3 | 45.4 | |

| Diameter | Gas inlet | A | 25 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 |

| Flue | ømm | 200 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 350 | 400 | |

| External size | Width(W) | mm | 1,240 | 1,240 | 1,240 | 1,240 | 1,240 | 1,240 | 1,240 | 1,470 | 1,610 | 1,630 |

| Length(L) | 2,500 | 2,560 | 2,710 | 2,760 | 2,810 | 3,180 | 3,500 | 3,240 | 3,640 | 3,920 | ||

| Height(H) | 1,570 | 1,570 | 1,570 | 1,570 | 1,570 | 1,570 | 1,570 | 2,340 | 2,340 | 2,530 | ||

| Product weight | kg | 1,380 | 1,450 | 1,570 | 1,600 | 1,650 | 1,800 | 2,030 | 2,580 | 3,100 | 3,750 | |

For heating and hot water circulation (333K → 343K) {60℃ → 70℃}

| Category | Unit | KDNV-G2X series | ||||||||||

| KDNV- 20G2X |

KDNV- 25G2X |

KDNV- 30G2X |

KDNV- 35G2X |

KDNV- 40G2X |

KDNV- 45G2X |

KDNV- 50G2X |

KDNV- 60G2X |

KDNV- 80G2X |

KDNV- 100G2X |

|||

| For heating and hot water circulation | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Circulation volume | ℓ | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 60,000 | 80,000 | 100,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||

| Head pressure loss | MPa{mH2O} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | |||

| Material | - | Stainless steel pipe | ||||||||||

| Connection diameter | A | 50 | 65 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | |

For hot water supply (298K → 338K) {25℃ → 65℃}

| Category | Unit | KDNV-G2X series | ||||||||||

| KDNV- 20G2X |

KDNV- 25G2X |

KDNV- 30G2X |

KDNV- 35G2X |

KDNV- 40G2X |

KDNV- 45G2X |

KDNV- 50G2X |

KDNV- 60G2X |

KDNV- 80G2X |

KDNV- 100G2X |

|||

| For hot water supply | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Hot water supply | ℓ | 5,000 | 6,250 | 7,500 | 8,750 | 10,000 | 11,250 | 12,500 | 15,000 | 20,000 | 25,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||

| Head pressure loss | MPa{mH2O} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | |||

| Material | - | Stainless steel pipe | ||||||||||

| Connection diameter | A | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 65 | |

For hot water supply (278K → 338K) {5℃ → 65℃}

| Category | Unit | KDNV-G2X series | ||||||||||

| KDNV- 20G2X |

KDNV- 25G2X |

KDNV- 30G2X |

KDNV- 35G2X |

KDNV- 40G2X |

KDNV- 45G2X |

KDNV- 50G2X |

KDNV- 60G2X |

KDNV- 80G2X |

KDNV- 100G2X |

|||

| For hot water supply | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Hot water supply | ℓ | 3,333 | 4,167 | 5,000 | 5,833 | 6,667 | 7,500 | 8,333 | 10,000 | 13,333 | 16,667 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||

| Head pressure loss | MPa{mH2O} | 0.015{0.15} | 0.018{0.18} | 0.015{0.15} | 0.02{0.2} | 0.018{0.18} | 0.02{0.2} | 0.024{0.24} | 0.033{0.33} | |||

| Material | - | Stainless steel pipe | ||||||||||

| Connection diameter | A | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 65 | |

-

The above specification table is indicated as follows.

- The fuel calorific value of fuel consumption is based on the low-level calorific value.

- Fuel: Higher calorific value _ Lower calorific value

- LNG : 11,000_10,000 kcal/N㎥

- Propane : 24,350_22,400 kcal/N㎥

- Design flow temperature condition for heating and hot water circulation 333~343K {60~70℃}

- Design flow temperature condition for hot water supply 298~338K {25~65℃}, 278~338K {5~65℃}

- The rated heat output for heating and hot water supply is given for each individual use, and in the case of simultaneous use, the total is the boiler heat output.

-

The following tolerances are included due to the measurement errors of the measuring instrument or measuring personnel.

- Boiler efficiency measurement error ±1%, fuel amount (heat input) measurement error ±1.5% - The above boiler efficiency is based on the true heat generation (low heat generation).

- The above specification table is subject to change without notice.

High efficiency vacuum hot water boiler

KDNV-G2HEX series

Operating principle and features

- The KDNV vacuum hot water boiler encloses a fixed amount of heating medium water and keeps it in a vacuum (negative pressure) state in the boiler body. When the medium water is heated, it immediately evaporates into decompressed steam to indirectly heat the heat exchanger to provide hygienic water

Multi-purpose heat exchangers

- Heat exchangers can be used for heating, hot water supply and circulation heating in 1~3 circuits depending on the user’s demand. Each heat exchanger is independently installed and provides hygienic water without water mixing.

Low NOx burner attached as default

- Fuel saving low NOx burner is attached as default and guarantees 40ppm or less when operating under 4% of O2

Absolutely safe design

- Unlike pressure boilers, the KDNV vacuum hot water boiler operates under negative pressure (pressure below atmospheric pressure) and has no risk of explosion. 4-level safety devices (Vacuum pressure, over heat prevention, boiler body thermistor and low water level switches) further ensures the reliability of the product.

Semi-permanent life

- As the boiler water (heating medium water) of the vacuum hot water boiler is always kept in a fixed amount under vacuum condition without moving, there are no risks of corrosion or scale accumulation caused by dissolved oxygen. In addition with hygienic high corrosion resistant stainless steel heat exchangers, the boiler body is semi-permanent.

Fuel cost reduction with high efficiency furnace design

- The high efficiency body design, which adopts once-through characteristics of the water tube boiler, forms the water cooling wall structure and heat absorbing 3-pass structure, greatly reduces fuel costs.

High efficiency economizer

- Condensing economizer can be attached to the flue to drastically reduce fuel cost (Option)

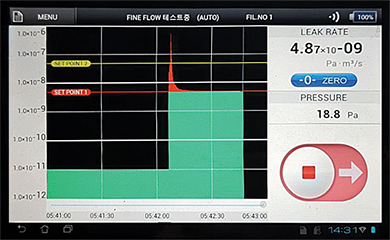

Helium gas leak detector

-

Check any leakage after processing the boiler body → Check any leakage after assembling the heat exchanger→ Check any leakage after assembling the finished product

To produce vacuum boilers with perfect vacuum condition, a helium gas leak detector is used in 3 steps during production. By using helium detector at near perfect vacuum condition of 10-3 Torr ~ 10-7 Torr, the system automatically detects even the smallest gap or air leak from the welded part, where no fluid can normally leak through.

tandard specifications for low NOx high-efficiency vacuum hot water boiler G2HEX series

| Category | Unit | KDNV-G2HEX series | ||||||||||||||||

| Hot water generator mounted type | ||||||||||||||||||

| KDNV- 20G2HEX |

KDNV- 25G2HEX |

KDNV- 30G2HEX |

KDNV- 35G2HEX |

KDNV- 40G2HEX |

KDNV- 45G2HEX |

KDNV- 50G2HEX |

KDNV- 60G2HEX |

KDNV- 80G2HEX |

KDNV- 100G2HEX |

KDNV- 120G2HEX |

KDNV- 130G2HEX |

KDNV- 150G2HEX |

KDNV- 160G2HEX |

KDNV- 180G2HEX |

KDNV- 200G2HEX |

|||

| Boiler specifications | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.09 | 2.33 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 1,800,000 | 2,000,000 | ||

| Efficiency | % | 98.3% | ||||||||||||||||

| Heating area | ㎡ | 10.1 | 10.1 | 10.1 | 11.0 | 11.0 | 12.2 | 12.2 | 14.5 | 18.2 | 19.9 | 22.0 | 22.0 | 25.0 | 25.0 | 28.0 | 31.0 | |

| Burner | - | MAXI 25(LX) | MAXI 32(LX) | P4M (LX) | P5M (LX) | P60M (LX) | P72M (LX) | P9M(LX) | S-4TG(LX) | |||||||||

| Burner capacity (MAX) |

kcal/h | 295,000 | 411,000 | 550,000 | 650,000 | 800,000 | 1,500,000 | 2,000,000 | 3,200,000 | |||||||||

| Control method | - | ON - OFF |

HI - LOW - OFF | HI - MIDDLE - LOW - OFF | ||||||||||||||

| Blower capacity | kW | 0.37 | 0.37 | 0.75 | 0.75 | 1.50 | 1.50 | 1.50 | 1.50 | 3.00 | 4.00 | 5.50 | 5.50 | 7.50 | 7.50 | 11.00 | 11.00 | |

| Total power consumption | kW | 0.47 | 0.47 | 0.85 | 0.85 | 1.60 | 1.60 | 1.60 | 1.60 | 3.10 | 4.10 | 5.60 | 5.60 | 7.60 | 7.60 | 11.10 | 11.10 | |

| Power | V | 220V x 1ø x 60Hz | 380V x 3ø x 60Hz | |||||||||||||||

| Fuel consumption | LNG | N㎥/h | 20.3 | 25.4 | 30.5 | 35.6 | 40.7 | 45.8 | 50.9 | 61.0 | 81.4 | 101.7 | 122.1 | 132.2 | 152.6 | 162.8 | 183.1 | 203.5 |

| Propane(LPG) | N㎥/h | 9.1 | 11.4 | 13.6 | 15.9 | 18.2 | 20.4 | 22.7 | 27.2 | 36.3 | 45.4 | 54.5 | 59.0 | 68.1 | 72.7 | 81.7 | 90.8 | |

| Diameter | Gas inlet | A | 25 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 65 | 65 | 65 |

| Flue | ømm | 200 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 350 | 350 | 400 | 400 | 450 | 450 | 450 | 500 | |

| External size | Width(W) | mm | 1,060 | 1,060 | 1,060 | 1,310 | 1,310 | 1,310 | 1,310 | 1,310 | 1,530 | 1,530 | 1,660 | 1,660 | 1,700 | 1,700 | 1,700 | 1,700 |

| Length(L) | 2,750 | 2,880 | 2,980 | 3,130 | 3,230 | 3,360 | 3,360 | 3,490 | 4,120 | 4,320 | 3,580 | 3,580 | 3,830 | 3,830 | 3,960 | 4,210 | ||

| Height(H) | 1,810 | 1,810 | 1,810 | 1,900 | 1,900 | 1,900 | 1,900 | 1,910 | 2,070 | 2,190 | 2,670 | 2,670 | 2,740 | 2,740 | 2,790 | 2,790 | ||

| Product weight | kg | 1,600 | 1,700 | 1,750 | 2,070 | 2,120 | 2,200 | 2,250 | 2,400 | 3,100 | 3,300 | 3,600 | 3,750 | 4,200 | 4,500 | 4,850 | 5,100 | |

For heating and hot water circulation (333K → 343K) {60℃ → 70℃}

| Category | Unit | KDNV- 20G2HEX |

KDNV- 25G2HEX |

KDNV- 30G2HEX |

KDNV- 35G2HEX |

KDNV- 40G2HEX |

KDNV- 45G2HEX |

KDNV- 50G2HEX |

KDNV- 60G2HEX |

KDNV- 80G2HEX |

KDNV- 100G2HEX |

KDNV- 120G2HEX |

KDNV- 130G2HEX |

KDNV- 150G2HEX |

KDNV- 160G2HEX |

KDNV- 180G2HEX |

KDNV- 200G2HEX |

|

| For heating and hot water circulation | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.09 | 2.33 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 1,800,000 | 2,000,000 | ||

| Circulation volume | ℓ | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 60,000 | 80,000 | 100,000 | 120,000 | 130,000 | 150,000 | 160,000 | 180,000 | 200,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||||||||

| Head pressure loss | MPa{mH2O} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | 0.02{0.2} | 0.022{0.22} | 0.033{0.33} | 0.03{0.3} | 0.02{0.2} | 0.022{0.22} | |||

| Material | - | Stainless steel pipe | ||||||||||||||||

| Connection diameter | A | 50 | 50 | 65 | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 150 | 150 | |

For hot water supply (298K → 338K) {25℃ → 65℃}

| Category | Unit | KDNV- 20G2HEX |

KDNV- 25G2HEX |

KDNV- 30G2HEX |

KDNV- 35G2HEX |

KDNV- 40G2HEX |

KDNV- 45G2HEX |

KDNV- 50G2HEX |

KDNV- 60G2HEX |

KDNV- 80G2HEX |

KDNV- 100G2HEX |

KDNV- 120G2HEX |

KDNV- 130G2HEX |

KDNV- 150G2HEX |

KDNV- 160G2HEX |

KDNV- 180G2HEX |

KDNV- 200G2HEX |

|

| For hot water supply | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.09 | 2.33 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 1,800,000 | 2,000,000 | ||

| Circulation volume | ℓ | 5,000 | 6,250 | 7,500 | 8,750 | 10,000 | 11,250 | 12,500 | 15,000 | 20,000 | 25,000 | 30,000 | 32,500 | 37,500 | 40,000 | 45,000 | 50,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||||||||

| Head pressure loss | MPa{mH2O} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.02{0.2} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | 0.02{0.2} | 0.022{0.22} | 0.033{0.33} | 0.03{0.3} | 0.02{0.2} | 0.022{0.22} | |||

| Material | - | Stainless steel pipe | ||||||||||||||||

| Connection diameter | A | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 100 | 100 | 100 | 100 | 100 | 100 | |

For hot water supply (278K → 338K) {5℃ → 65℃}

| Category | Unit | KDNV- 20G2HEX |

KDNV- 25G2HEX |

KDNV- 30G2HEX |

KDNV- 35G2HEX |

KDNV- 40G2HEX |

KDNV- 45G2HEX |

KDNV- 50G2HEX |

KDNV- 60G2HEX |

KDNV- 80G2HEX |

KDNV- 100G2HEX |

KDNV- 120G2HEX |

KDNV- 130G2HEX |

KDNV- 150G2HEX |

KDNV- 160G2HEX |

KDNV- 180G2HEX |

KDNV- 200G2HEX |

|

| For hot water supply | Rated heat output | MW | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.09 | 2.33 |

| kcal/h | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 1,800,000 | 2,000,000 | ||

| Circulation volume | ℓ | 3,333 | 4,167 | 5,000 | 5,833 | 6,667 | 7,500 | 8,333 | 10,000 | 13,333 | 16,667 | 20,000 | 21,667 | 25,000 | 26,667 | 30,000 | 33,333 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | ||||||||||||||||

| Head pressure loss | MPa{mH2O} | 0.015{0.15} | 0.018{0.18} | 0.015{0.15} | 0.02{0.2} | 0.018{0.18} | 0.02{0.2} | 0.024{0.24} | 0.033{0.33} | 0.02{0.2} | 0.022{0.22} | 0.033{0.33} | 0.03{0.3} | 0.02{0.2} | 0.022{0.22} | |||

| Material | - | Stainless steel pipe | ||||||||||||||||

| Connection diameter | A | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 65 | 100 | 100 | 100 | 100 | 100 | 100 | |

-

The above specification table is indicated as follows.

- The fuel calorific value of fuel consumption is based on the following.

- Fuel: Higher calorific value _ Lower calorific value

- LNG : 11,000_10,000 kcal/N㎥

- Propane : 24,350_22,400 kcal/N㎥

- Design flow temperature condition for heating and hot water circulation 333~343K {60~70℃}

- Design flow temperature condition for hot water supply 298~338K {25~65℃}, 278~338K {5~65℃}

- The rated heat output for heating and hot water supply is given for each individual use, and in the case of simultaneous use, the total is the boiler heat output.

-

The following tolerances are included due to the measurement errors of the measuring instrument or measuring personnel.

- Boiler efficiency measurement error ±1%, fuel amount (heat input) measurement error ±1.5% - The above boiler efficiency is based on the true heat generation (low heat generation).

- The above specification table is subject to change without notice.

Vacuum hot water boiler

KDNV series in the small capacity type, KDNV series in the large capacity type

KDNV series in the small capacity type

KDNV series in the large capacity type

Operating principle and features

- The KDNV vacuum hot water boiler encloses a fixed amount of heating medium water and keeps it in a vacuum (negative pressure) state in the boiler body. When the medium water is heated, it immediately evaporates into decompressed steam to indirectly heat the heat exchanger to provide hygienic water

Fuel cost reduction with high efficiency furnace design

- The high efficiency body design, which adopts once-through characteristics of the water tube boiler, forms the water cooling wall structure and heat absorbing 3-pass structure, greatly reduces fuel costs.

Easy handling, no license and inspection required

- Anyone can operate The KDNV vacuum hot water boiler as it is exempt from all laws and regulations in Korea (By law, the boiler is viewed as explosion-free boiler as it operates below atmospheric pressure). No license or inspection are required for operation.

Easy maintenance

- Attaching the artificial intelligence D-Brain enables the easier operation and management. (Option)

Absolutely safe design

- Unlike pressure boilers, the KDNV vacuum hot water boiler operates under negative pressure (pressure below atmospheric pressure) and has no risk of explosion. 4-level safety devices (Vacuum pressure, over heat prevention, boiler body thermistor and low water level switches) further ensures the reliability of the product.

Semi-permanent life

- As the boiler water (heating medium water) of the vacuum hot water boiler is always kept in a fixed amount under vacuum condition without moving, there are no risks of corrosion or scale accumulation caused by dissolved oxygen. In addition with hygienic high corrosion resistant stainless steel heat exchangers, the boiler body is semi-permanent.

Multi-purpose heat exchangers

- Heat exchangers can be used for heating, hot water supply and circulation heating in 1~3 circuits depending on the user’s demand. Each heat exchanger is independently installed and provides hygienic water without water mixing.

Low NOx Burner

- Fuel cost can be saved by attaching a low NOx burner and 40ppm or less of NOx is guaranteed when operating under 4% of O2

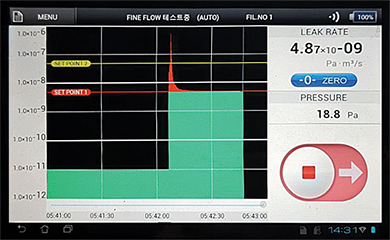

Helium gas leak detector

-

Check any leakage after processing the boiler body → Check any leakage after assembling the heat exchanger→ Check any leakage after assembling the finished product

To produce vacuum boilers with perfect vacuum condition, a helium gas leak detector is used in 3 steps during production. By using helium detector at near perfect vacuum condition of 10-3 Torr ~ 10-7 Torr, the system automatically detects even the smallest gap or air leak from the welded part, where no fluid can normally leak through.

Standard specifications for vacuum hot water boiler KDNV series

| Category | Unit | KDNV- 10 |

KDNV- 15 |

KDNV- 20 |

KDNV- 25 |

KDNV -30 |

KDNV- 35 |

KDNV- 40 |

KDNV- 45 |

KDNV- 50 |

KDNV- 60 |

KDNV- 80 |

KDNV-100 | KDNV-120 | KDNV-130 | KDNV-150 | KDNV-160 | KDNV-200 | KDNV-250 | KDNV-300 | |

| Boiler specifications | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.29 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.70 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.33 | 2.91 | 3.49 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 2,000,000 | 2,500,000 | 3,000,000 | ||

| Efficiency | % | 91% or more | |||||||||||||||||||

| Heating area | ㎡ | 5.43 | 5.85 | 8.28 | 8.28 | 10.09 | 10.09 | 12.04 | 12.04 | 18 | 18 | 20 | 22 | 22 | 24 | 28 | 28 | 36 | 38 | 42 | |

| Control method | - | ON - OFF | HI - LOW - OFF | ||||||||||||||||||

| Total power consumption | kW | 0.3(0.25) | 0.3(0.35) | 0.47(0.47) | 0.47(0.47) | 0.84(0.84) | 1.2(1.2) | 1.6(1.2) | 2.3(1.9) | 2.3(3.1) | 4.1(3.1) | 4.1(7.6) | 11(7.6) | 15(7.6) | 18.5(11.1) | ||||||

| Power | V | 220V x 1ø x 60Hz | 380V x 3ø x 60Hz | ||||||||||||||||||

| Retained heating medium water volume | L | 200 | 220 | 300 | 330 | 390 | 400 | 470 | 480 | 500 | 550 | 650 | 700 | 750 | 790 | 830 | 900 | 1,300 | 1,600 | 1,900 | |

| Fuel consumption | LNG | N㎥/h | 11.0 | 16.5 | 22.0 | 27.5 | 33.0 | 38.5 | 44.0 | 49.5 | 54.9 | 65.9 | 87.9 | 109.9 | 131.9 | 142.9 | 164.8 | 175.8 | 219.8 | 274.7 | 329.7 |

| Propane(LPG) | 4.9 | 7.4 | 9.8 | 12.3 | 14.7 | 17.2 | 19.6 | 22.1 | 24.5 | 29.4 | 39.2 | 49.1 | 58.9 | 63.8 | 73.6 | 78.5 | 98.1 | 122.6 | 147.2 | ||

| Butane | 3.7 | 5.6 | 7.5 | 9.3 | 11.2 | 13.0 | 14.9 | 16.8 | 18.6 | 22.4 | 29.8 | 37.3 | 44.7 | 48.4 | 55.9 | 59.6 | 74.5 | 93.1 | 111.8 | ||

| Diesel | kg/h | 10.7 | 16.0 | 21.3 | 26.7 | 32.0 | 37.3 | 42.7 | 48.0 | 53.3 | 64.0 | 85.4 | 106.7 | 128.0 | 138.7 | 160.0 | 170.7 | 213.4 | 266.7 | 320.1 | |

| Connection diameter | Oil inlet | A | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Gas inlet | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 65 | ||

| Flue | ømm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 300 | 300 | 350 | 350 | 350 | 400 | 400 | 400 | 500 | 550 | 600 | |

| Base size | Width(W) | mm | 1,060 | 1,060 | 1,200 | 1,200 | 1,300 | 1,300 | 1,450 | 1,450 | 1,140 | 1,140 | 1,440 | 1,510 | 1,510 | 1,510 | 1,530 | 1,530 | 1,790 | 2,100 | 3,100 |

| Length(L) | 1,060 | 1,060 | 1,200 | 1,200 | 1,300 | 1,300 | 1,450 | 1,450 | 2,500 | 2,730 | 2,260 | 2,260 | 2,260 | 2,260 | 2,560 | 2,560 | 2,870 | 3,400 | 3,800 | ||

| Height(H) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||

| External size (Gas) |

Width(W) | mm | 860 | 860 | 1,000 | 1,000 | 1,100 | 1,100 | 1,250 | 1,250 | 1,140 | 1,140 | 1,440 | 1,510 | 1,510 | 1,510 | 1,530 | 1,530 | 1,890 | 2,000 | 2,180 |

| Length(L) | 1,370 | 1,370 | 1,640 | 1,640 | 1,740 | 1,810 | 2,000 | 2,000 | 3,270 | 3,570 | 3,610 | 3,640 | 3,640 | 3,690 | 3,960 | 3,960 | 4,730 | 5,120 | 5,280 | ||

| Height(H) | 1,640 | 1,640 | 1,870 | 1,870 | 1,900 | 1,900 | 1,920 | 1,920 | 1,570 | 1,570 | 2,170 | 2,340 | 2,340 | 2,340 | 2,530 | 2,530 | 2,580 | 2,720 | 2,860 | ||

| External size (Diesel) |

Width(W) | mm | 860 | 860 | 1,000 | 1,000 | 1,100 | 1,100 | 1,250 | 1,250 | 1,140 | 1,140 | 1,440 | 1,510 | 1,510 | 1,510 | 1,530 | 1,530 | 1,890 | ||

| Length(L) | 1,350 | 1,350 | 1,530 | 1,530 | 1,630 | 1,730 | 1,940 | 1,940 | 3,150 | 3,390 | 3,230 | 3,370 | 3,370 | 3,420 | 3,710 | 3,710 | 4,510 | ||||

| Height(H) | 1,640 | 1,640 | 1,870 | 1,870 | 1,900 | 1,900 | 1,920 | 1,920 | 1,570 | 1,570 | 2,170 | 2,340 | 2,340 | 2,340 | 2,530 | 2,530 | 2,580 | ||||

| Product weight | kg | 500 | 520 | 700 | 720 | 870 | 900 | 1,100 | 1,150 | 1,250 | 1,900 | 2,750 | 3,320 | 3,500 | 3,820 | 4,250 | 4,500 | 5,200 | 5,650 | 6,800 | |

- The external size may vary depending on the control panel and burner specifications.

- Specifications in ( ) are diesel boiler specifications.

For heating and hot water circulation (333K → 343K) {60℃ → 70℃}

| Category | Unit | KDNV -10 |

KDNV -15 |

KDNV -20 |

KDNV -25 |

KDNV -30 |

KDNV -35 |

KDNV -40 |

KDNV -45 |

KDNV -50 |

KDNV -60 |

KDNV -80 |

KDNV -100 |

KDNV -120 |

KDNV -130 |

KDNV -150 |

KDNV -160 |

KDNV -200 |

KDNV -250 |

KDNV -300 |

|

| For heating and hot water circulation | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.28 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.7 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.33 | 2.01 | 3.49 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 2,000,000 | 2,500,000 | 3,000,000 | ||

| Circulation volume | ℓ | 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | 60,000 | 80,000 | 100,000 | 120,000 | 130,000 | 150,000 | 160,000 | 200,000 | 250,000 | 300,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||||||||||||

| Pressure loss | MPa{mH2O} | 0.012{0.12} | 0.017{0.17} | 0.02{0.2} | 0.018{0.18} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | 0.022{0.22} | 0.03{0.3} | 0.033{0.33} | 0.035{0.35} | 0.04{0.4} | ||||||||

| Material | - | Stainless steel pipe | |||||||||||||||||||

| Connection diameter | A | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | 100 | 150 | 150 | 150 | |

For hot water supply (298K → 338K) {25℃ → 65℃}

| Category | Unit | KDNV -10 |

KDNV -15 |

KDNV -20 |

KDNV -25 |

KDNV -30 |

KDNV -35 |

KDNV -40 |

KDNV -45 |

KDNV -50 |

KDNV -60 |

KDNV -80 |

KDNV -100 |

KDNV -120 |

KDNV -130 |

KDNV -150 |

KDNV -160 |

KDNV -200 |

KDNV -250 |

KDNV -300 |

|

| For hot water supply | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.28 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.7 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.33 | 2.01 | 3.49 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 2,000,000 | 2,500,000 | 3,000,000 | ||

| Circulation volume | ℓ | 2,500 | 3,750 | 5,000 | 6,250 | 7,500 | 8,750 | 10,000 | 11,250 | 12,500 | 15,000 | 20,000 | 25,000 | 30,000 | 32,500 | 40,000 | 40,000 | 40,000 | 62,500 | 75,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||||||||||||

| Pressure loss | MPa{mH2O} | 0.06{0.06} | 0.015{0.15} | 0.018{0.18} | 0.015{0.15} | 0.02{0.2} | 0.024{0.24} | 0.033{0.33} | 0.022{0.22} | 0.03{0.3} | 0.022{0.22} | 0.035{0.35} | 0.04{0.4} | ||||||||

| Material | - | Stainless steel pipe | |||||||||||||||||||

| Connection diameter | A | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 65 | 80 | 80 | 80 | 100 | 100 | |

For hot water supply (278K → 338K) {5℃ → 65℃}

| Category | Unit | KDNV -10 |

KDNV -15 |

KDNV -20 |

KDNV -25 |

KDNV -30 |

KDNV -35 |

KDNV -40 |

KDNV -45 |

KDNV -50 |

KDNV -60 |

KDNV -80 |

KDNV -100 |

KDNV -120 |

KDNV -130 |

KDNV -150 |

KDNV -160 |

KDNV -200 |

KDNV -250 |

KDNV -300 |

|

| For hot water supply | Rated heat output | MW | 0.12 | 0.17 | 0.23 | 0.28 | 0.35 | 0.41 | 0.47 | 0.52 | 0.58 | 0.7 | 0.93 | 1.16 | 1.40 | 1.51 | 1.74 | 1.86 | 2.33 | 2.01 | 3.49 |

| kcal/h | 100,000 | 150,000 | 200,000 | 250,000 | 300,000 | 350,000 | 400,000 | 450,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,300,000 | 1,500,000 | 1,600,000 | 2,000,000 | 2,500,000 | 3,000,000 | ||

| Circulation volume | ℓ | 1,667 | 2,500 | 3,333 | 4,167 | 5,000 | 5,833 | 6,667 | 7,500 | 8,333 | 10,000 | 13,333 | 16,667 | 20,000 | 21,667 | 25,000 | 26,667 | 33,333 | 41,667 | 50,000 | |

| Maximum operating pressure | MPa{kgf/㎠} | 1{10} | |||||||||||||||||||

| Pressure loss | MPa{mH2O} | 0.06{0.06} | 0.015{0.15} | 0.018{0.18} | 0.015{0.15} | 0.02{0.2} | 0.024{0.24} | 0.033{0.33} | 0.022{0.22} | 0.03{0.3} | 0.022{0.22} | 0.035{0.35} | 0.04{0.4} | ||||||||

| Material | - | Stainless steel pipe | |||||||||||||||||||

| Connection diameter | A | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 65 | 80 | 80 | 80 | 100 | 100 | |

-

The above specification table is indicated as follows.

- The fuel calorific value of fuel consumption is based on the low-level calorific value.

- LNG : 10,000 kcal/N㎥

- LPG(Propane) : 22,400 kcal/N㎥

- LPG(Butane) : 29,500 kcal/N㎥

- Diesel:10,300 kcal/kg(gravity:0.836)

- Design flow temperature condition for heating and hot water circulation 333~343K {60~70℃}

- Design flow temperature condition for hot water supply 298~338K {25~65℃}, 278~338K {5~65℃}

- The rated heat output for heating and hot water supply is given for each individual use, and in the case of simultaneous use, the total is the boiler heat output.

-

The following tolerances are included due to the measurement errors of the measuring instrument or measuring personnel.

- Boiler efficiency measurement error ±1% - The above boiler efficiency is based on the true heat generation (low heat generation).

- The above specification table is subject to change without notice.

- This specification is based on a gas boiler. For detailed specifications, refer to the specification table.