- High efficiency low NOx Condensing boiler

- Low NOx 3-pass flue and smoke tube steam boiler

- Small capacity flue and smoke tube steam boiler

- Z-MINI flue and smoke tube steam boiler

- Two circuit flue and smoke tube hot water boiler

- Flue and smoke tube hot water boiler

- NAVAL flue and smoke tube hot water boiler

High efficiency low NOx Condensing boiler

KDFC series

The condensing boiler maximizes the boiler efficiency by recovering the sensible heat of the exhaust gas generated during boiler operation and the condensed latent heat of water vapor by attaching air pre-heater and economizer to the main body.

Feature

- The boiler maximizes energy efficiency by recovering the sensible heat contained in the exhaust gas and the latent heat of water vapor.

- The boiler is integrated with auxiliary facilities such as the blower, water pump, panel water meter and automatic blow device.

- The boiler does not require a separate installation space by attaching the original air pre-heater and economizer directly to the boiler.

Standard specifications for condensing flue and smoke tube type of steam boiler KDFC series

| Item | Model | Unit | KDFC -1000HEX |

KDFC -15HEX |

KDFC -20HEX |

KDFC -25HEX |

KDFC -30HEX |

KDFC -35HEXB |

KDFC -40HEXB |

KDFC -45HEX |

KDFC -50HEXB |

KDFC -60HEX |

KDFC -70HEX |

KDFC -80HEX |

KDFC -100HEX |

| Boiler specifications | Rated evaporation | kg/h | 1,000 | 1,500 | 2,000 | 2,500 | 3,000 | 3,500 | 4,000 | 4,500 | 5,000 | 6,000 | 7,000 | 8,000 | 10,000 |

| Medium hot water | Gcal/h | 1G | 1.5G | 2G | 2.5G | 3G | 3.5G | 4G | 4.5G | 5G | 6G | ||||

| Maximum operating pressure | Mpa[kg/㎠] | 1{10} | |||||||||||||

| Heat output | MW | 0.75 | 1.12 | 1.50 | 1.87 | 2.25 | 2.62 | 2.99 | 3.37 | 3.74 | 4.49 | 5.24 | 5.99 | 7.48 | |

| kcal/h | 643,700 | 965,550 | 1,287,400 | 1,609,250 | 1,931,100 | 2,252,950 | 2,574,800 | 2,896,650 | 3,218,500 | 3,862,200 | 4,505,900 | 5,149,600 | 6,437,000 | ||

| Efficiency | % | 99% | |||||||||||||

| Heating area | ㎡ | 16 | 26 | 34 | 40 | 47 | 54 | 61 | 68 | 74 | 91 | 104 | 119 | 150 | |

| Power | V | 380V / 440V x 3ø x 60Hz | |||||||||||||

| Burner | Combustion control | - | HI - LOW - OFF / HI - MID - LOW - OFF / proportional control | ||||||||||||

| Burner type | Forced mixing type | ||||||||||||||

| Ignition method | Pilot ignition method | ||||||||||||||

| Air pre-heater | Model | - | Heat pipe type | ||||||||||||

| Product weight | kg | 194 | 219 | 255 | 278 | 320 | 362 | 371 | 388 | 403 | 529 | 613 | 678 | 749 | |

| Water pre-heater | Model | - | Spiral type | ||||||||||||

| Product weight | kg | 164 | 279 | 330 | 376 | 388 | 473 | 512 | 544 | 631 | 674 | 687 | 726 | 894 | |

| Fuel consumption | LNG | N㎥/h | 65.0 | 97.5 | 130.0 | 162.6 | 195.1 | 227.6 | 260.1 | 292.6 | 325.1 | 390.1 | 455.1 | 520.2 | 650.2 |

| Propane | N㎥/h | 29.0 | 43.5 | 58.1 | 72.6 | 87.1 | 101.6 | 116.1 | 130.6 | 145.1 | 174.2 | 203.2 | 232.2 | 290.3 | |

| kg/h | 57.0 | 85.5 | 114.0 | 142.6 | 171.1 | 199.6 | 228.1 | 256.6 | 285.1 | 342.2 | 399.2 | 456.2 | 570.3 | ||

| Power consumption | Water pump | Model | Vertical multi-step | ||||||||||||

| kW x Quantity | 2.2 X 2 | 3.0X2 | 3.7X2 | 5.5X2 | 7.5X2 | ||||||||||

| Blower | kW | 3.7 | 7.5 | 11 | 15 | 19 | 22 | 30 | 37 | ||||||

| Connection diameter | Steam outlet | A | 50 | 65 | 80 | 80 | 80 | 80 | 100 | 100 | 125 | 125 | 150 | 150 | 200 |

| Water inlet | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | ||

| Drainage outlet | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | ||

| Gas inlet | 25 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | ||

| Safety valve | 25 X 1 | 40 X 1 | 40 X 1 / 25 X 1 | 40x2 | 50 X 1 / 40 X 1 | 65X1 / 50X1 | |||||||||

| Exhaust outlet | mm | 300x430 | 380x475 | 400x600 | 400x600 | 380x700 | 480x700 | 480x720 | 480x720 | 480x770 | 546x750 | 546x860 | 546x930 | 600x950 | |

| Flue | ø | 300 | 350 | 400 | 400 | 450 | 450 | 500 | 550 | 550 | 600 | 650 | 700 | 800 | |

| External size | Width(W) | mm | 1,826 | 2,111 | 2,136 | 2,241 | 2,351 | 2,416 | 2,461 | 2,461 | 2,531 | 2,596 | 2,828 | 2,871 | 3,140 |

| Length(L) | 3,566 | 3,599 | 3,828 | 3,938 | 4,142 | 4,865 | 4,657 | 5,057 | 4,953 | 5,455 | 5,645 | 5,992 | 6,873 | ||

| Height(H) | 2,781 | 3,061 | 3,236 | 3,326 | 3,376 | 3,324 | 3,394 | 3,394 | 3,660 | 3,862 | 3,945 | 4,157 | 4,328 | ||

| Weight | Ton | 4.0 | 5.3 | 6.1 | 6.9 | 7.7 | 8.8 | 9.5 | 10.0 | 11.2 | 13.0 | 14.5 | 17.0 | 20.5 | |

-

The above specification table is indicated as follows. Fuel consumption is based on the low-level calorific value.

- LNG : 10,000 kcal/N㎥

- Propane(LPG) : 22,400 kcal/N㎥ - The rated evaporation amount is based on the water supply temperature of 20℃ and steam pressure of 1MPa.

- These specifications are subject to change without prior notice to improve product performance.

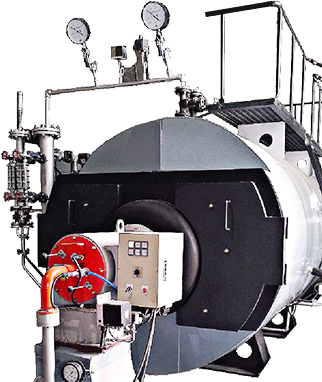

Low NOx 3-pass flue and smoke tube steam boiler

KDF series

Feature

- 3-pass structure

- Easy to replace and repair the flue with handy open-close 2-door smoke room design.

- The boiler has excellent sudden load fluctuation response ability as the body contains large amount of retained water.

- High heat absorption rate by designing the rear combustion chamber wet type

- The flue tube can be used safely as it is designed to cope with thermal expansion by making it in a waveform.

Standard specifications for 3-pass flue and smoke tube type of low NOx boiler KDF series

| Category | Unit | KDF -1000 |

KDF -1500 |

KDF -2000 |

KDF -2500 |

KDF -3000 |

KDF -3500 |

KDF -4000 |

KDF -4500 |

KDF -5000 |

KDF -6000 |

KDF -7000 |

KDF -8000 |

KDF -10000 |

|

| Boiler specifications | Rated evaporation | kg/h | 1,000 | 1,500 | 2,000 | 2,500 | 3,000 | 3,500 | 4,000 | 4,500 | 5,000 | 6,000 | 7,000 | 8,000 | 10,000 |

| Medium hot water | Gcal/h | 1G | 1.5G | 2G | 2.5G | 3G | 3.5G | 4G | 4.5G | 5G | 6G | ||||

| Maximum operating pressure | Mpa[kg/㎠] | 1{10} | |||||||||||||

| Heat output | MW | 0.75 | 1.12 | 1.50 | 1.87 | 2.25 | 2.62 | 2.99 | 3.37 | 3.74 | 4.49 | 5.24 | 5.99 | 7.48 | |

| kcal/h | 643,700 | 965,550 | 1,287,400 | 1,609,250 | 1,931,100 | 2,252,950 | 2,574,800 | 2,896,650 | 3,218,500 | 3,862,200 | 4,505,900 | 5,149,600 | 6,437,000 | ||

| Efficiency | % | 88% | |||||||||||||

| Heating area | ㎡ | 26 | 33 | 41 | 51 | 62 | 70 | 81 | 91 | 101 | 110 | 121 | 138 | 175 | |

| Power | V | 380V / 440V x 3ø x 60Hz | |||||||||||||

| Burner | Combustion control | - | HI - LOW - OFF / HI - MID - LOW - OFF / proportional control | ||||||||||||

| Burner type | Forced mixing type | ||||||||||||||

| Ignition method | Pilot ignition method | ||||||||||||||

| Fuel consumption | LNG | N㎥/h | 73.1 | 109.7 | 146.3 | 182.9 | 219.4 | 256.0 | 292.6 | 329.2 | 365.7 | 438.9 | 512.0 | 585.2 | 731.5 |

| LPG +AIR | 52.2 | 78.4 | 104.5 | 130.6 | 156.7 | 182.9 | 209.0 | 235.1 | 261.2 | 313.5 | 365.7 | 418.0 | 522.5 | ||

| Propane | 32.7 | 49.0 | 65.3 | 81.6 | 98.0 | 114.3 | 130.6 | 146.9 | 163.3 | 195.9 | 228.6 | 261.2 | 326.6 | ||

| Butane | 24.8 | 37.2 | 49.6 | 62.0 | 74.4 | 86.8 | 99.2 | 111.6 | 124.0 | 148.8 | 173.6 | 198.4 | 248.0 | ||

| Power consumption | Water pump | Model | Vertical multi-step | ||||||||||||

| kW x Quantity | 2.2 X 2 | 3.0X2 | 3.7X2 | 5.5X2 | 7.5X2 | ||||||||||

| Blower | kW | 3.7 | 7.5 | 11 | 15 | 19 | 22 | ||||||||

| Connection diameter | Steam outlet | A | 50 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 150 | 150 | 200 |

| Water inlet | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | ||

| Drainage outlet | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | ||

| Gas inlet | 25 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 65 | 80 | 80 | ||

| Safety valve | 25 X 1 | 32X1 | 40X1 | 32X1/25X1 | 40X1 / 25X1 | 40X2 | 40x1/32X1 | 40X2 | 50 X 1 / 40 X 1 | 65X1 / 50X1 | |||||

| Exhaust outlet | mm | 250X400 | 250X550 | 300X600 | 300X750 | 400X750 | 400X800 | 400X950 | 500X950 | 500X950 | 600X950 | 600X900 | 700X950 | 700X950 | |

| Flue | ø | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 600 | 650 | 650 | 650 | 700 | 800 | |

| External size | Width(W) | mm | 2,178 | 2,278 | 2,408 | 2,408 | 2,498 | 2,605 | 2,705 | 2,852 | 2,852 | 2,660 | 2,810 | 3,010 | 3,120 |

| Length(L) | 3,553 | 3,715 | 3,968 | 4,448 | 5,069 | 5,075 | 5,275 | 5,375 | 5,575 | 5,600 | 6,200 | 6,500 | 6,960 | ||

| Height(H) | 2,796 | 2,896 | 3,031 | 3,031 | 3,131 | 3,251 | 3,351 | 3,501 | 3,501 | 2,860 | 3,060 | 3,250 | 3,320 | ||

| Weight | Ton | 4.6 | 6.8 | 8.4 | 9.1 | 11.0 | 12.6 | 13.5 | 15.4 | 15.9 | 16.4 | 17.6 | 19.2 | 22.5 | |

-

The above specification table is indicated as follows. Fuel consumption is based on the low-level calorific value.

- LNG : 10,000 kcal/N㎥

- LPG + AIR : 14,000 kcal/N㎥

- Propane(LPG) : 22,400 kcal/N㎥

- Butane : 29,500 kcal/N㎥ - The rated evaporation amount is based on the water supply temperature of 20℃ and steam pressure of 1MPa.

- These specifications are subject to change without prior notice to improve product performance.

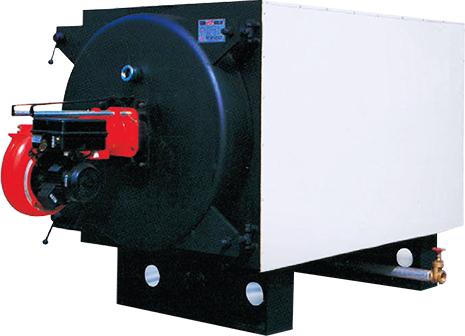

Small capacity flue and smoke tube steam boiler

S-MINI series

Feature

- The first Korean boiler to adopt 3-pass structured horizontal flue in industrial boiler

- Easy to replace and repair the flue with handy open-close smoke room door design.

- Cylindrical design provides high safety, easy clean and maintenance.

- Good for use in poor water quality conditions such as groundwater, etc.

- Combustion of bunker C oil is also possible.

- Continuous supply of highly dried and high-quality steam.

- Narrow width design allow easy installation even in small spaces.

Standard specifications for flue and smoke tube type of steam boiler

| Category | Unit | S-MINI series in the small capacity | |||

| S-MINI - 10 | S-MINI - 20 | S-MINI - 30 | |||

| Boiler specifications | Rated evaporation | kg/h | 100 | 200 | 300 |

| Maximum operating pressure | Mpa[㎏/㎠] | 0.35 [3.5] | |||

| Heat output | MW | 0.07 | 0.15 | 0.22 | |

| kcal/h | 63,490 | 126,980 | 190,470 | ||

| Efficiency | % | 86 | |||

| Weight | kg | - | |||

| Operating power | V | 220V × 1ø x 60Hz | |||

| Combustion method | - | Forced press-in ventilation type | |||

| Control method | - | ON-OFF | |||

| Retaining quantity | kg | - | |||

| Fuel consumption | Boiler kerosene | kg/h | 8.7 | 17.3 | 26.0 |

| Heavy oil | 8.0 | 16.0 | 24.0 | ||

| LNG | N㎥/h | 7.4 | 14.8 | 22.1 | |

| Propane | 3.3 | 6.6 | 9.9 | ||

| LPG+AIR | 5.3 | 10.7 | 16.1 | ||

| Power consumption | Water pump | kW | 0.4 | 0.4 | 0.75 |

| Oil heater | 2.0 | 2.0 | 2.0 | ||

| Oil pump | - | - | - | ||

| Burner motor | 0.4 | 0.4 | 0.4 | ||

| Connection diameter | Main steam valve | A | 25 | 32 | 40 |

| Safety valve | 25 | 40 | 50 | ||

| Water supply valve | 25 | 25 | 25 | ||

| Drainage valve | 40 | 40 | 40 | ||

| Water supply inlet | - | - | - | ||

| Gas inlet | - | - | - | ||

| Exhaust outlet | ø mm | - | - | - | |

| Flue | 150 | 200 | 200 | ||

| External size | Width(W) | mm | 960 | 1,160 | 1,160 |

| Length(L) | 1,760 | 1,940 | 2,100 | ||

| Height(H) | 1,150 | 1,520 | 1,520 | ||

-

Fuel consumption is based on the low-level calorific value.

- Low-level calorific value

① Boiler kerosene : 43,116kJ/kg{10,300kcal/kg}

② Heavy oil : 40,813kJ/kg{9,750kcal/kg}

③ LNG : 41.9KJ/N㎥{10,000kcal/N㎥}

④ Propane : 93.8KJ/N㎥{22,400kcal/N㎥}

⑤ LPG+AIR : 57.8KJ/N㎥{13,800kcal/N㎥}

- The rated evaporation amount is based on the water supply temperature of 20℃, steam pressure of 0.35Mpa {3.5kg/㎠} and 1Mpa {10kg/㎠}.

- The efficiency measurement of the boiler is based on the low-level calorific value of the fuel and the value at the time of rating.

- These specifications are subject to change without prior notice to improve product performance.

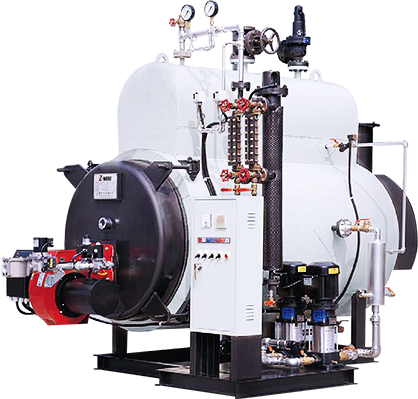

Z-MINI flue and smoke tube steam boiler

Z-MINI Series

Feature

- 3-pass structure

- High efficiency by using the special spiral flue.

- Easy to replace and repair the flue with handy open-close smoke room door design.

- Easy to clean, inspect and maintain.

- Steam generation is fast (dry steam is generated 6-10 minutes after ignition) and thermal efficiency is high as the retained water of the boiler is small.

- Requires only 1/2 installation space compare to existing boilers of the same capacity.

- Attaching the artificial intelligence controller D-Brain enables the easier operation and management. (Optional)

Standard specifications for flue and smoke tube type of steam boiler

| Category | Unit | Z-MINI series in the ultra-small capacity | ||||||||||

| Z-MINI - 50 | Z-MINI - 80 | Z-MINI - 100 | Z-MINI - 150 | Z-MINI - 200 | Z-MINI - 250 | Z-MINI - 300 | Z-MINI - 500 | Z-MINI - 800 | Z-MINI - 1000 | |||

| Boiler specifications | Rated evaporation | kg/h | 500 | 800 | 1,000 | 1,500 | 2,000 | 2,500 | 3,000 | 5,000 | 8,000 | 10,000 |

| Maximum operating pressure | Mpa[㎏/㎠] | 1 [10] | ||||||||||

| Heat output | MW | 0.38 | 0.6 | 0.75 | 1.12 | 1.5 | 1.87 | 2.25 | 3.74 | 5.99 | 7.49 | |

| kcal/h | 321,850 | 514,960 | 643,700 | 965,550 | 1,287,400 | 1,609,250 | 1,931,100 | 3,218,500 | 5,149,600 | 6,437,000 | ||

| Efficiency | % | 88% | ||||||||||

| Weight | kg | 2,250 | 2,410 | 2,500 | 2,650 | 2,900 | 3,410 | 3,550 | 4,310 | 5,620 | 7,020 | |

| Operating power | V | 220V × 3ø x 60Hz / 380V × 3ø x 60Hz × 4W | ||||||||||

| Combustion method | - | Forced mixing type | ||||||||||

| Control method | - | High - Low - Off / Fully Automatic | ||||||||||

| Retaining quantity | kg | 800 | 850 | 920 | 980 | 1,050 | 1,410 | 1,520 | 1,850 | 2,310 | 2,650 | |

| Fuel consumption | Boiler kerosene | kg/h | 41.7 | 66.7 | 83.5 | 125.3 | 167.1 | 208.9 | 250.6 | 417.6 | 668.6 | 835.7 |

| Heavy oil | 38.5 | 61.7 | 77.1 | 115.7 | 154.2 | 192.7 | 231.4 | 385.6 | 617.1 | 771.3 | ||

| LNG | N㎥/h | 36.6 | 58.5 | 73.1 | 109.7 | 146.3 | 182.9 | 219.4 | 365.7 | 585.2 | 731.5 | |

| Propane | 16.3 | 26.1 | 32.7 | 49.0 | 65.3 | 81.6 | 98.0 | 163.3 | 261.2 | 326.6 | ||

| LPG+AIR | 25.8 | 41.4 | 51.7 | 77.6 | 103.5 | 129.4 | 155.3 | 258.8 | 414.1 | 517.7 | ||

| Power consumption | Water pump | kW | 1.5X2 | 1.5X2 | 2.2X2 | 2.2X2 | 2.2X2 | 2.2X2 | 3.7X2 | 3.7X2 | 5X2 | 5X2 |

| Oil heater | 5 | 5 | 6 | 6 | 9 | 9 | 10 | 16 | 20 | 20 | ||

| Oil pump | 0.4 | 0.4 | 0.4 | 0.4 | 0.75 | 0.75 | 0.75 | 2.2 | 3.7 | 3.7 | ||

| Burner motor | 1.5 | 2.2 | 2.2 | 3.7 | 5.5 | 7.5 | 7.5 | 15.0 | 19.0 | 22.0 | ||

| Connection diameter | Main steam valve | A | 40 | 50 | 50 | 65 | 80 | 80 | 80 | 125 | 150 | 200 |

| Safety valve | 25 | 25 | 25 | 32 | 40 | 40 | 40 | 40,40 | 40,50 | 50,50 | ||

| Water supply valve | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 50 | 50 | ||

| Drainage valve | ||||||||||||

| Water supply inlet | 15 | 15 | 15 | 20 | 20 | 25 | 25 | 32 | 40 | 40 | ||

| Gas inlet | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 80 | 100 | ||

| Exhaust outlet | ø mm | 250X350 | 300X380 | 300X400 | 300X440 | 350X500 | 400X550 | 400X580 | 450X600 | 500X700 | 550X800 | |

| Flue | ||||||||||||

| External size | Width(W) | mm | 1,550 | 1,850 | 1,850 | 1,900 | 1,970 | 2,070 | 2,150 | 2,300 | 2,550 | 2,800 |

| Length(L) | 2,850 | 3,600 | 3,800 | 4,000 | 4,450 | 4,900 | 5,050 | 5,350 | 5,600 | 5,950 | ||

| Height(H) | 2,050 | 2,400 | 2,400 | 2,450 | 2,580 | 2,680 | 2,800 | 3,050 | 3,250 | 3,450 | ||

-

Fuel consumption is based on the low-level calorific value.

- Low-level calorific value

① Boiler kerosene : 43,116kJ/kg{10,300kcal/kg}

② Heavy oil : 40,813kJ/kg{9,750kcal/kg}

③ LNG : 41.9KJ/N㎥{10,000kcal/N㎥}

④ Propane : 93.8KJ/N㎥{22,400kcal/N㎥}

⑤ LPG+AIR : 57.8KJ/N㎥{13,800kcal/N㎥}

- The rated evaporation amount is based on the water supply temperature of 20℃, steam pressure of 0.35Mpa {3.5kg/㎠} and 1Mpa {10kg/㎠}.

- The efficiency measurement of the boiler is based on the low-level calorific value of the fuel and the value at the time of rating.

- These specifications are subject to change without prior notice to improve product performance.

Flue and smoke tube hot water boiler

SUPER series

Principle and structure

- It is a high-performance, high efficiency boiler that has unique 3-pass combustion structure and eccentric corrugated combustion chamber that facilitates hot water circulation inside the boiler body and greatly increases the heat exchanger heat absorption.

Feature

- Both hot water and heating can be solved at the same time with one boiler.

- Scale generation and dissolved oxygen corrosion are reduced by attaching the heat exchanger to the inside of the boiler.

- Smoking chamber has no risk of collapse as it is made with fire-resistant bricks and is made as water-room type to maximize heating surface.

- The heating surface of the heat exchanger, which is the life of a hot water boiler, is expanded as much as possibly by designing the copper pipe installation of the heat exchanger with the largest capacity in Korea (Containing 8-10% more than the actual required amount).

Standard specifications for the flue and smoke tube type of hot water boiler

| Category | Unit | Standard specifications for flue and smoke tube 2-circuit type of SUPER series | ||||||

| SUPER - 30 | SUPER - 40 | SUPER - 50 | SUPER - 60 | SUPER - 80 | SUPER - 100 | |||

| Boiler body | Rated heat output | MW | 0.35 | 0.47 | 0.58 | 0.7 | 0.93 | 1.16 |

| kcal/h | 300,000 | 400,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Maximum operating pressure | Mpa[㎏/㎠] | 0.35 [3.5] | 0.35 [3.5], 0.7 [7], 1.0 [10] (Optional) | |||||

| Efficiency | % | 88% | ||||||

| Operating power | V | 220V x 3ø x 60Hz / 380V x 3ø x 60Hz x 4W | ||||||

| Burner output | kW | 0.3(0.25) | 0.3(0.35) | 0.47(0.47) | 2.2 | 2.2 | 0.7 | |

| Fuel consumption | Boiler kerosene | kg/h | 39.8 | 53 | 66.3 | 79.5 | 106 | 132.5 |

| Heavy oil | 36.7 | 49.1 | 61.3 | 73.6 | 98.1 | 122.6 | ||

| LNG | N㎥/h | 34.1 | 45.4 | 56.8 | 68.2 | 90.9 | 113.6 | |

| Propane | 15.2 | 20.3 | 25.4 | 30.4 | 40.6 | 50.7 | ||

| LPG+AIR | 24.7 | 32.9 | 41.1 | 49.4 | 65.8 | 82.3 | ||

| Connection diameter | Heating Inlet and Outlet | A | 80 | 100 | 100 | 125 | 125 | 150 |

| Heating Inlet and Outlet | 50 | 50 | 50 | 50 | 65 | 65 | ||

| Drainage valve | 32 | 32 | 32 | 40 | 50 | 50 | ||

| Flue | ø | 250 | 300 | 300 | 300 | 350 | 400 | |

| External size | Width(W) | mm | 1,440 | 1,500 | 1,500 | 1,500 | 1,680 | 1,720 |

| Length(L) | 2,100 | 2,300 | 2,460 | 2,620 | 2,830 | 3,060 | ||

| Height(H) | 1,690 | 1,780 | 1,780 | 1,920 | 2,150 | 2,270 | ||

-

Fuel consumption in the above specification table is based on the following..

- Low-level calorific value

① Boiler kerosene : 44,116kJ/kg{10,300kcal/kg}

② Heavy oil : 40,813kJ/kg{9,750kcal/kg}

③ LNG : 41.9KJ/N㎥{10,000kcal/N㎥}

④ Propane : 93.8KJ/N㎥{22,400kcal/N㎥}

⑤ LPG+AIR : 57.8KJ/N㎥{13,800kcal/N㎥}

- These specifications are subject to change without prior notice to improve product performance.

Flue and smoke tube type of hot water boiler

MEC Series

Principle and structure

- The boiler is made in the high performance of the package type in very high thermal efficiency using the combustion chamber made of a corrugated flue tube and the smoke tube using the steel pipe for boilers.

Feature

- It shows the best performance with the pressurized combustion method in the optimum design.

- The thermal efficiency is high by adopting the complete 3-pass combustion method, and the facility cost is drastically reduced due to the pack cage type.

- The heat absorption effect is maximized by designing and manufacturing the front and rear combustion chambers as water rooms in order to minimize the heat dissipation loss.

- Easy to replace and repair the flue with handy open-close smoke room door design.

Standard specifications for the flue and smoke tube type of hot water boiler

| Category | Unit | Standard specifications for flue and smoke tube type of hot water boiler MEC series | ||||||

| MEC - 30 | MEC - 40 | MEC - 50 | MEC - 60 | MEC - 80 | MEC - 100 | |||

| Boiler body | Rated heat output | MW | 0.35 | 0.47 | 0.58 | 0.7 | 0.93 | 1.16 |

| kcal/h | 300,000 | 400,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | ||

| Maximum operating pressure | Mpa[㎏/㎠] | 0.35 [3.5] | 0.35 [3.5], 0.7 [7], 1.0 [10] (Optional) | |||||

| Efficiency | % | 88% | ||||||

| Operating power | V | 220V x 3ø x 60Hz / 380V x 3ø x 60Hz x 4W | ||||||

| Burner output | kW | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | |

| Fuel consumption | Boiler kerosene | kg/h | 39.8 | 53 | 66.3 | 79.5 | 106 | 132.5 |

| Heavy oil | 36.7 | 49.1 | 61.3 | 73.6 | 98.1 | 122.6 | ||

| LNG | N㎥/h | 34.1 | 45.4 | 56.8 | 68.2 | 90.9 | 113.6 | |

| Propane | 15.2 | 20.3 | 25.4 | 30.4 | 40.6 | 50.7 | ||

| LPG+AIR | 24.7 | 32.9 | 41.1 | 49.4 | 65.8 | 82.3 | ||

| Connection diameter | Heating Inlet and Outlet | A | 80 | 100 | 100 | 125 | 125 | 150 |

| Heating Inlet and Outlet | 80 | 100 | 100 | 125 | 125 | 150 | ||

| Drainage valve | 32 | 32 | 32 | 40 | 50 | 50 | ||

| Flue | ø | 250 | 300 | 300 | 300 | 350 | 400 | |

| External size | Width(W) | mm | 2,200 | 2,350 | 2,510 | 2,700 | 2,850 | 3,050 |

| Length(L) | 1,400 | 1,520 | 1,630 | |||||

| Height(H) | 1,690 | 1,780 | 1,920 | 2,150 | 2,270 | |||

-

Fuel consumption in the above specification table is based on the following..

- Low-level calorific value

① Boiler kerosene : 44,116kJ/kg{10,300kcal/kg}

② Heavy oil : 40,813kJ/kg{9,750kcal/kg}

③ LNG : 41.9KJ/N㎥{10,000kcal/N㎥}

④ Propane : 93.8KJ/N㎥{22,400kcal/N㎥}

⑤ LPG+AIR : 57.8KJ/N㎥{13,800kcal/N㎥}

- These specifications are subject to change without prior notice to improve product performance.

NAVAL flue and smoke tube hot water boiler

DN series

Feature

- High performance and high efficiency are maintained as it is manufactured with a combustion structure of the inverted combustion of the 3-pass method adopting a special spiral pipe

- Inside can be aluminum metalized when used for hygienic hot water supply

- Easy to replace and repair the flue with handy open-close smoke room door design.

- It is a high-end product with high performance and high efficiency that minimizes heat loss in the front flue chamber made with the latest technology in Europe and Dongkwang's know-how by technology provided from Naval, Italy.

Standard specifications for NAVAL flue and smoke tube hot water boiler DN series

| Category | Unit | DN - 10 | DN - 20 | DN - 30 | DN - 40 | DN - 50 | DN - 60 | DN - 80 | DN - 100 | DN - 120 | DN - 150 | DN - 180 | DN - 200 | |

| Boiler body | Rated heat output | MW | 0.12 | 0.23 | 0.35 | 0.47 | 0.58 | 0.7 | 0.93 | 1.16 | 1.39 | 1.75 | 2.09 | 2.33 |

| kcal/h | 100,000 | 200,000 | 300,000 | 400,000 | 500,000 | 600,000 | 800,000 | 1,000,000 | 1,200,000 | 1,500,000 | 1,800,000 | 2,000,000 | ||

| Maximum operating pressure | Mpa[㎏/㎠] | 0.35 [3.5], 0.7 [7], 1.0 [10] (Optional) | ||||||||||||

| Efficiency | % | 88% | ||||||||||||

| Operating power | V | 220V × 1ø x 60Hz | 220V × 3ø x 60Hz / 380V × 3ø x 60Hz × 4W | |||||||||||

| Burner output | kW | 0.4 | 0.4 | 0.75 | 0.75 | 1.1 | 1.5 | 2.2 | 2.2 | 3.7 | 5.5 | 7 | 11 | |

| Fuel consumption | Boiler kerosene | kg/h | 13.3 | 26.5 | 39.8 | 53.1 | 66.9 | 79.6 | 106.3 | 132.9 | 159.4 | 174.1 | 239.1 | 265.8 |

| Heavy oil | 12.2 | 24.5 | 36.7 | 49 | 61.3 | 73.6 | 98.1 | 122.6 | 147.1 | 184 | 220.7 | 245.4 | ||

| LNG | N㎥/h | 11.4 | 22.7 | 34.1 | 45.4 | 56.8 | 68.2 | 90.9 | 113.6 | 136.4 | 170.4 | 204.5 | 227.3 | |

| Propane | 5.1 | 10.1 | 15.2 | 20.3 | 25.4 | 30.4 | 40.6 | 50.7 | 60.9 | 76.1 | 91.3 | 101.5 | ||

| LPG+AIR | 8.2 | 16.4 | 24.7 | 32.9 | 41.1 | 49.4 | 65.8 | 82.3 | 98.8 | 123.5 | 148.2 | 164.5 | ||

| Diameter | Hot water inlet and outlet | A | 50 | 65 | 80 | 100 | 100 | 100 | 100 | 125 | 150 | 150 | 150 | 200 |

| Drainage valve | 25 | 25 | 32 | 32 | 32 | 32 | 40 | 40 | 50 | 50 | 50 | 50 | ||

| Flue | ømm | 150 | 200 | 250 | 300 | 300 | 300 | 350 | 400 | 400 | 450 | 450 | 450 | |

| External size | Width(W) | mm | 850 | 920 | 1,010 | 1,010 | 1,130 | 1,130 | 1,250 | 1,250 | 1,400 | 1,400 | 1,600 | 1,600 |

| Length(L) | 2,190 | 2,170 | 3,050 | 3,260 | 3,450 | 3,500 | 3,600 | 3,650 | 3,720 | 3,800 | 4,050 | 4,200 | ||

| Height(H) | 1,260 | 1,360 | 1,430 | 1,430 | 1,550 | 1,550 | 1,700 | 1,750 | 1,830 | 1,900 | 2,050 | 2,150 | ||

-

Fuel consumption in the above specification table is based on the following.

- Low-level calorific value

① Boiler kerosene : 43,116kJ/kg{10,300kcal/kg}

② Heavy oil : 40,813kJ/kg{9,750kcal/kg}

③ LNG : 41.9KJ/N㎥{10,000kcal/N㎥}

④ Propane : 93.8KJ/N㎥{22,400kcal/N㎥}

⑤ LPG+AIR : 57.8KJ/N㎥{13,800kcal/N㎥}

- These specifications are subject to change without prior notice to improve product performance.